The applications for indoor and outdoor LED fixtures have become almost limitless. Indoor lighting applications are ideal for, but not limited to, schools, food processing plants, warehousing, manufacturing facilities, office buildings, and a wide range of retail lighting. Outdoor applications can range from site and area lighting to parking garage and street lighting. Regardless of the configuration, all fixtures consist of a light source, a driver/controller, and optics.

The applications for indoor and outdoor LED fixtures have become almost limitless. Indoor lighting applications are ideal for, but not limited to, schools, food processing plants, warehousing, manufacturing facilities, office buildings, and a wide range of retail lighting. Outdoor applications can range from site and area lighting to parking garage and street lighting. Regardless of the configuration, all fixtures consist of a light source, a driver/controller, and optics.

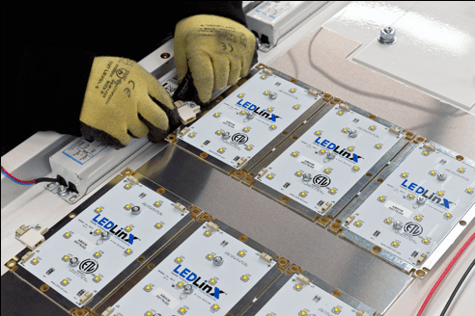

Light Source

A LED is a special type of PN junction diode encased by a hard, transparent epoxy resin body. Forward biasing the p-n junction of the LED with a direct current supply causes the device to convert electrical energy into single color light. The epoxy-resin body not only protects the semiconductor from vibration and shock but also focuses light photons through the top of the structure.

Given the different applications for LEDs, distinct categories exist. Miniature LEDs may work as indicators. Application-specific LEDs function in alphanumeric displays, light bars, signs, and applications that require flashing indicators or color indicators. High power LEDs have the higher luminosity needed for headlights, street lights, and industrial lighting. While miniature and application-specific LEDs emit light without producing large amounts of heat, high power LEDs generate heat and must mount on heat absorbent material.

Driver

LEDs require regulated voltage and constant current. If the forward voltage for an LED decreases, the amount of current drawn by the device increases. Every increase in current causes an increase in generated heat that can lead to a breakdown called thermal runaway. This issue becomes compounded with the use of high power LEDs.

Drivers may integrate as part of a LED bulb or mount as an external self-contained power supply connected through a wiring harness regulate power to a LED or LED arrays. Low-voltage DC input drivers have input voltages range from 5 to 32VDC and provide reliable operation. High voltage AC input drivers have input voltages that range from 120 to 227VAC and work for large residential, commercial, and industrial applications.

Some lighting fixtures may use an additional switching power supply that allows the versatility and efficiency of a low voltage driver to control dimming and outputs. Housings used for lighting fixtures may also provide additional thermal management for high power LEDS with fans, heat sinks, and airflow guides.

Optics

LEDs produce concentrated light that loses intensity over distance. To compensate for the loss of intensity, many LED fixtures include secondary optics. Depending on the application, the secondary optics may consist of lenses, reflectors, and diffusers or total internal reflection (TIR) optics that include a lens and reflector. All this works to collect light, increase intensity, and focus light onto a surface. Texturing the surface enhances beam and color uniformity needed for quality lighting.

Interested in learning more about LED basics? Check out our other posts about Color Temperature and Lumens!